Skype

hualianpm

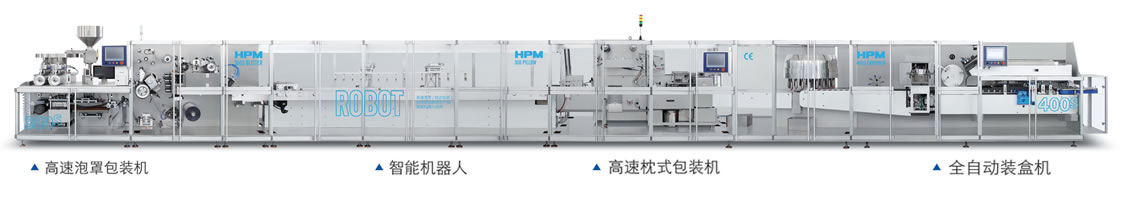

This production line is suitable for high-speed aluminum-plastic packaging of medicines, especially capsules, tablets, and sugar-coated tablets. It automatically detects and rejects waste. The intelligent robot automatically queues up and sends it to the high-speed pillow packaging machine to seal the three sides of the medicine board and pass the servo The rotating suction head enters the cartoning machine. The high-speed automatic cartoning machine loads the medicine board and instructions into the carton and seals the box for batch number. The whole process of fully automatic packaging can achieve the purpose of reducing space and saving labor. High automation and cleanliness are more in line with GMP requirements. .

Technical features

1. Using DPH-380S (D) high-speed blister packaging machine can high-speed aluminum-plastic packaging of various regular medicines, including high-speed automatic feeding, and high-speed detection and rejection.

2. The first dual-tracking robot to transfer the stabilized medicine board to the pillow packer conveying station. It can ensure the stability of the medicine board conveying process without collision.

3. The selected HXZB-420-300 full-servo high-speed pillow wrapping machine can stably reach a speed of 300 packets/min

4. Use DXH-400S(D) automatic cartoning machine to achieve high speed matching.

5. Multi-station servo rotating suction head realizes perfect synchronization from pillow wrapping machine to cartoning machine.

6. High-end full-servo blister packaging machine and automatic cartoning machine can be selected, and the main motor is a servo motor, which is an economical solution that cooperates with the robot to achieve synchronous connection.

Main technical parameters:

| DPH-380S High Speed Blister Packaging Machine | ||

| project | parameter | |

| Punching speed (standard version 90mm×57mm) | 30-100 times/min online speed | |

| production capacity | 180-600 version/min | |

| Optional range of feed stroke | 20-120mm | |

| Forming area | 360X260mm | |

| Forming depth | ≤13mm | |

|

Packaging Material |

Pharmaceutical PVC | 0.25X380mm |

| Aluminum foil PTP | 0.02X380mm | |

| Air consumption | ≥30 m3/h | |

| compressed air pressure | 0.6-0.8Mpa | |

| Power and total power | Three-phase five-wire 380V 50HZ 30KW | |

| Overall dimensions of the whole machine (length X width X height) | 4050X1030X1750mm | |

| weight | 3500Kg | |

| HXZB420/300 High Speed Pillow Packaging Machine | |

| Production speed | 30-300 packs/min |

| bag size | Length 110-150mm, width 20-140mm, thickness 5-35mm |

| Packaging material thickness | composite membrane |

| Packaging Materials | <420 |

| Packaging material thickness | The best thickness is 3-7 silk |

| Rated frequency | 50Hz |

| Air compressor | >0.15m3/min |

| Rated voltage | 220V |

| total power | 11kw |

| machine weight | 2000kg |

| Dimensions | L×W×H (L×W×H) 7700×1200×1800mm |

| DXH-400S High Speed Cartoning Machine | |

| project | parameter |

| Pack box speed speed | 100-400 boxes/min |

| Version block rule inch (L*W*H) | (65-105)*(30-70)*(4-12)mm |

| Paper box rule inch (L*W*H) | (90-170)*(35-80)*(15-50)mm |

| Say ming book foot inch (L*W*H) | (100-320)*(100-210)mm |

| Air consumption | ≥2 m3/h |

| compressed air pressure | 0.5-0.7Mpa |

| Power and total power | Three-phase five-wire 380V 50HZ 10KW |

| Dimensions (length X width X height) | 5300X1700X1750mm |

| weight | 5500Kg |