Skype

hualianpm

Company based on the domestic pharmaceutical equipment market, for FDA, G M P on the pharmaceutical industry's specific requirements, the introduction of the international advanced level of pharmaceutical processing equipment technology and design concepts, product technology level living in the domestic leading position. Company's products cover the pharmaceutical, food, beverage, alcohol, chemical and other fields.

|

Business Scope: 1, traditional Chinese medicine extraction, enrichment, alcohol precipitation tank and alcohol recovery system equipment and engineering installation. 2, small injection, large infusion ingredients system and process piping design and engineering installation. 3, bio-pharmaceutical, blood products, reaction tank and process piping design and engineering installation. 4, the fermentation tank, animal breeding reaction tank and process piping design and engineering installation. 5, reactor, crystallization tank, CIP cleaning system and other ... ... |

|

|

Engineering design concept: 1, engineering design and engineering leading ideology has a high degree of agreement. 2, the design of each system to ensure the reliability of its performance. 3, the system can avoid direct or indirect pollution of the product. 4, with advanced and unique welding technology. 5, the system in full compliance with FDA / G M P requirements. |

|

|

CIP Cleaning System: 1, less cleaning fluid consumption. 2, reduce the cleaning time. 3, increase the utilization of equipment. 4, increase the operational safety. 5, the cleaning process to confirm the effect through the sensor. |

|

|

Advanced extraction equipment: 1, extraction tank structure is divided into: straight type, positive cone, mushroom-style, oblique cone, inverted cone and so on. 2, The structure of the inspection door of the extraction tank is as follows: "gas" sealing structure of rotary slag door, "pneumatic" sealing structure of spiral arm type slag gate and "pneumatic" sealing structure. 3, extraction tank complete sets of equipment including: defoamers, condensers, coolers, automatic oil-water separator, liquid pumps, filters and related pipelines. 4, the extraction tank to check the filter are: single-fixed out of the filter, double-fixed composite out of the filter, side arm-type slag filter. 5, extraction tank extraction: dynamic extraction, static extraction, multi-function extraction and heat reflux extraction process. 6, static extraction tank pressure way: mechanical rotary "pressure to mention" structure, automatic rotary "pressure to mention" structure. |

|

|

Energy-saving enrichment equipment: 1, the functional structure of the division are: single-effect outer loop concentrator, double-effect outer loop concentrator, three-effect outer loop concentrator, scraper concentrator, spherical concentrator, vacuum decompression concentrator, falling film evaporator, Circulation evaporator and so on. 2, according to the characteristics of different materials to choose different structure of the concentrator to achieve the best concentration effect. 3, a reasonable design to ensure solvent recovery ≥ 95%, effectively reduce production costs. 4, the optimal design can control the degree of vacuum gradient to achieve the minimum energy consumption. 5, the unique form of defoaming to achieve the concentration of different materials. 6, advanced evaporation chamber and other structures to ensure that no loss of materials. 7, a reasonable insulation design to achieve the lowest energy consumption and the impact on the operating temperature. 8, a reasonable layout to reduce the equipment footprint, investment costs to achieve controllable. 9, a unique design to achieve automatic drainage and concentrate recovery. 10, according to different structural dimensions designed to meet different evaporation requirements. 11, the scientific structure designed to achieve the best cleaning results. |

|

|

Scientific precipitation process: 1, a variety of heat transfer structure: standard jacket, honeycomb board jacket, coil jacket. 2, dynamic mixing structure is divided into: propulsion, vane, and modular. 3, maintenance-free mechanical seal to ensure that the -0.1-0.6 Mpa pressure range of normal use 4, in accordance with the requirements of the design process of different height to diameter ratio of the tank in order to achieve the best surface layer. 5, cold light explosion-proof light + long plate liquid level mirror to achieve the perfect combination of quantitative liquid. 6, the structure of the original electric controllable supernatant outlet device to ensure a quantitative control of liquid. 7, the traditional side rotation adjustable supernatant outlet device to meet the needs of non-occasions. 8, the unique combination of pneumatic slag + pneumatic mixing device to ensure clean slag. 9, the overall insulation, clean the surface treatment equipment to fully meet the requirements of the pharmaceutical industry. |

|

|

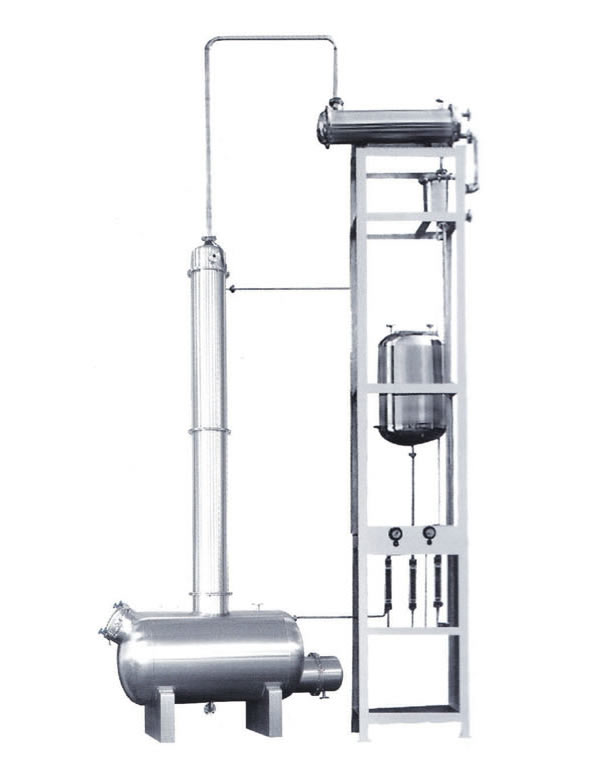

Efficient alcohol recovery system: 1, according to the process needs to achieve continuous feed and intermittent feed. 2, according to different concentrations of recycled sub-layer into the liquid or return. 3, a variety of unique structure of the distributor effectively enhance the recovery of concentration. 4, according to different occasions, the use of vertical or horizontal kettle body to meet different needs. 5, efficient plate heat exchanger and tube condensing recovery system 6, multi-stage temperature monitoring system to achieve different concentrations and efficiency. 7, the overall insulation to ensure that enhance the recovery efficiency and reduce energy consumption. 8, removable stainless steel corrugated packing to achieve the best gas and liquid conversion. 9, through a variety of optimized design to ensure that the concentration of alcohol recovery 93-95%. 10, the perfect process design to achieve ≤ 1% of environmentally friendly emissions of alcohol |

|