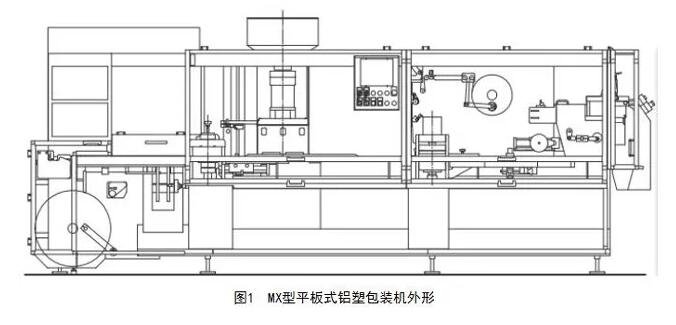

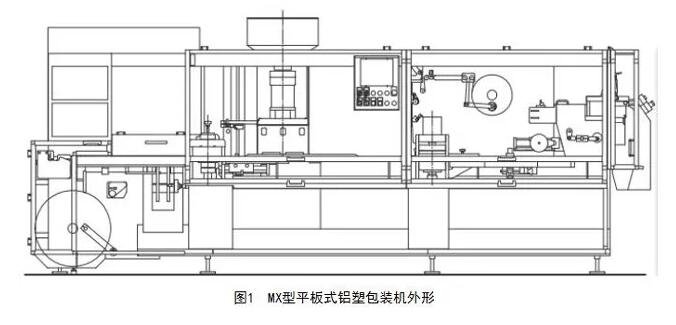

The shape of the MX type flat

blister packaging machine is shown in Figure 1. The production process is as follows:

After the PVC film is preheated, it is pulled by the clamp to reach the molding die, and the lower die is lifted under the driving of the forming cam. After the PVC film is pressed in close contact with the fixed upper die, the forming head in the upper die chamber is lowered by the cylinder. The heated PVC film is extruded and stretched. After the forming head returns to the position, the lower mold is lowered, the mold is opened, and the three sets of clamps (connected together by the connecting rod) simultaneously pull the PVC film, and sequentially complete the filling of the pills, the photographic detection, After heat sealing (synchronized with molding), coding, cutting, rejecting and other stations, it is transported into the product tote or downstream cartoning machine.

The main motor of the

blister packaging machine is a brake motor with an electromagnet and brake control. Under normal circumstances, the equipment stops, the electromagnet is de-energized, and the brake pads return to the position under the spring tension. The rotor of the motor can be locked and the spindle does not rotate due to the inertia of the machine drive cam. The cutting device is controlled separately by the servo motor.

According to the different production specifications (ie, the size of the product blister board and the traction stroke, etc.), the spindle of the equipment rotates for one week, and the cutting mechanism can perform 1 to 3 cuttings under the control of the setting parameters, and can be cut each time. 1 to 3 boards are not equal. The spindle design speed can reach up to 50 r/min, and the maximum production capacity of the machine can reach 300 boards/min.