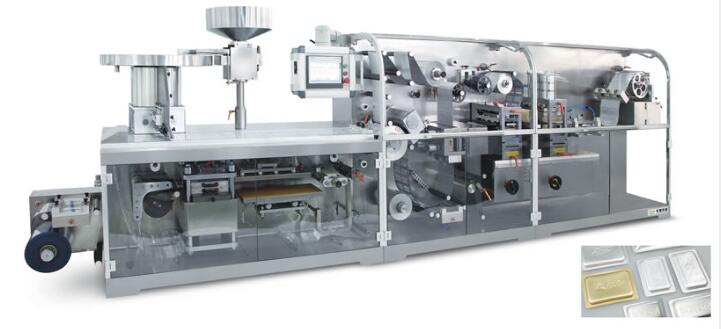

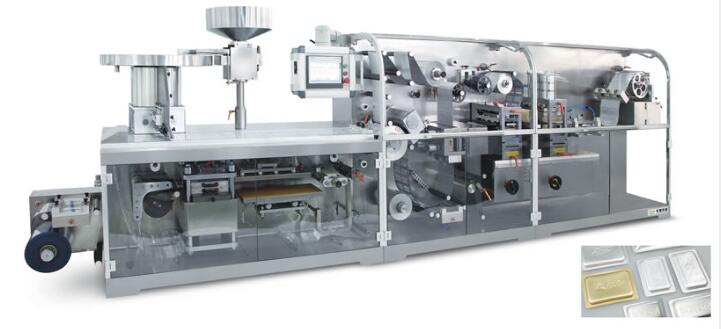

Eleven standard specification references for blister packaging machine operations:

1. Dial the power switch to open the water supply valve;

2. Press the preheat switch and heater switch to respectively heat the PVC heating roller (adjust to 155~160°C), aluminum foil heating roller (adjust to 185~190°C) and batch number steel heating (120~130°C) ;

3. Put PVC and aluminum foil in the specified direction, and make the name of the aluminum foil drug consistent with the direction of the batch. Put the PVC around the heating roller on the forming roller and finally join the aluminum foil at the aluminum foil heating roller.

4. When the predetermined temperature is reached, press the start switch, the main unit rotates clockwise, and PVC bypasses the PVC heating roller, the feeding hopper, the aluminum foil heating roller, the tensioning wheel, the batch number device, and the punching die.

5. Press the “press, cut, vacuum, batch” button and start switch. The machine rotates to check whether the die-cut aluminum-plastic finished product meets the requirements. The batch number steel font should be consistent with the font direction on the aluminum foil. If the opposite is true, the aluminum foil can be exchanged. Or the direction of the batch number of steel.

6. Check whether the aluminum-plastic finished product has a clear mesh, whether the batch number is clear, whether the aluminum-plastic composite is flat, whether the punching is complete, and whether the batch number is perforated or the like.

7. After checking the requirements, the machine is running normally, put down the hopper, and add the sifted qualified intermediate products.

8. Open the discharge valve, adjust the feeding speed to be consistent with the machine speed, press the “brush wheel” switch to adjust the normal speed, so as not to affect the quality of the intermediate product;

9. The machine is running normally and the production operation begins.

10. During the production process, the appearance quality of the aluminum-plastic finished product must be checked frequently, and the operation of the machine should be stopped immediately if abnormal, and it can be produced after normal operation;

11. After the production is finished, press the main stop switch to turn off the cooling water.

Blister packaging machine operation safety matters specification:

(1) Personnel handling and repairing aluminum-plastic packaging machines should be trained in professional technology.

(2) During the operation of the aluminum-plastic packaging machine, it is forbidden to open the safety protection device for various operations.

(3) Do not open the protection device of the transmission mechanism for any operation during the operation of the aluminum-plastic packaging machine.

(4) If it is necessary to operate in the operation of the aluminum-plastic packaging machine, there must be a guardian present, and it is absolutely forbidden to touch any active part.

(5) All electrical parts (parts) on this aluminum-plastic packaging machine are prohibited from being touched and replaced by non-electrician personnel.

(6) The aluminum-plastic packaging machine is prohibited from starting frequently, and the interval is 5 seconds.

(7) The equipment must be powered off during maintenance and commissioning.

blister packaging machine